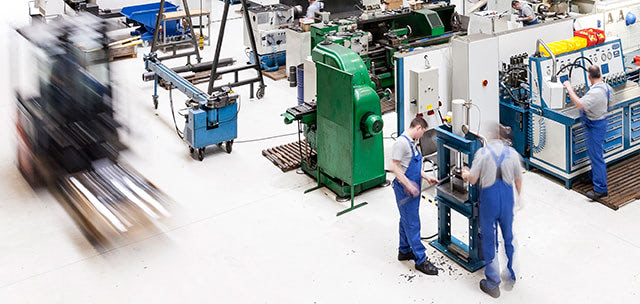

Our company’s main activity is the planning, production, installation, maintenance and repair of special purpose machinery and production lines. We offer our clients a comprehensive service from conception to implementation. Over the past few decades we have successfully completed nearly 500 individual projects in almost every sector of the industry. Besides the planning and manufacturing of custom-made machines, we undertake the transformation, modernization and renovation of existing machines.

Machinery

From planning to realisation

Unique single-purpose machines, manufacturing appliances

As a manufacturer of unique machines we do not have a perpetual choice of products; we design and manufacture optimal single-purpose machines, production lines, assembly lines, processing machines, assembly plants, automatic or semi-automatic equipments on the basis of the demands of our partners. Within the machine manufacturing process our own in-house engineer team is responsible for the survey of the buyers’ demands, elaboration of the machine’s construction, calculations, mechanic and electric design, elaboration of the measuring and controlling techniques, programming and commissioning of single-purpose machines. Approval of the final plans is followed by the start of the manufacturing processes for which sufficient room is ensured by our modern manufacturing halls. In our own manufacturing workshops we are able to satisfy the entire demand for unique components necessary for single-purpose machine manufacturing and thereby the manufacturing period is significantly shortened. Our activities include modernisation and successive automation of existing machines, machine lines, manufacturing lines as well as inserting new components into a manufacturing system. Almost all orders entail new research and development activities that are aimed mostly on the solution of automation processes. In the course of manufacturing unique machines, a basic criterion is the compliance with high quality and safety requirements.

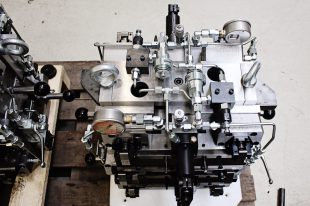

Hydraulic power supplies

Our firm has been planning and manufacturing hydraulic power supplies designed to meet unique demands and in this process important aspects are energy efficiency, environment friendly technology and increased life-span. As regards size, we manufacture power supplies that can be categorised as mini, medium and large, which could be manufactured with prefabricated, fixed size aluminium and plate reservoir design, as well as with unique design and size corresponding to the specific demands of the equipment. The complexity of a hydraulic power supply is determined by the functional and technological demand of the equipment operated by it. Technologically determined basic components of power supplies include pump unit, gauge, thermometer, screening unit with obstruction detector, cooling unit, valve block and the valves, furthermore an electronic control unit necessary for its operation. Modular design of the power supplies enables successive assembly of supplementary components, variability of the hydraulic valve system. Systems composed of premium category building blocks provide always optimal solution, should you be in need of a uniquely designed power supply, contact our engineers for a proposed solution.

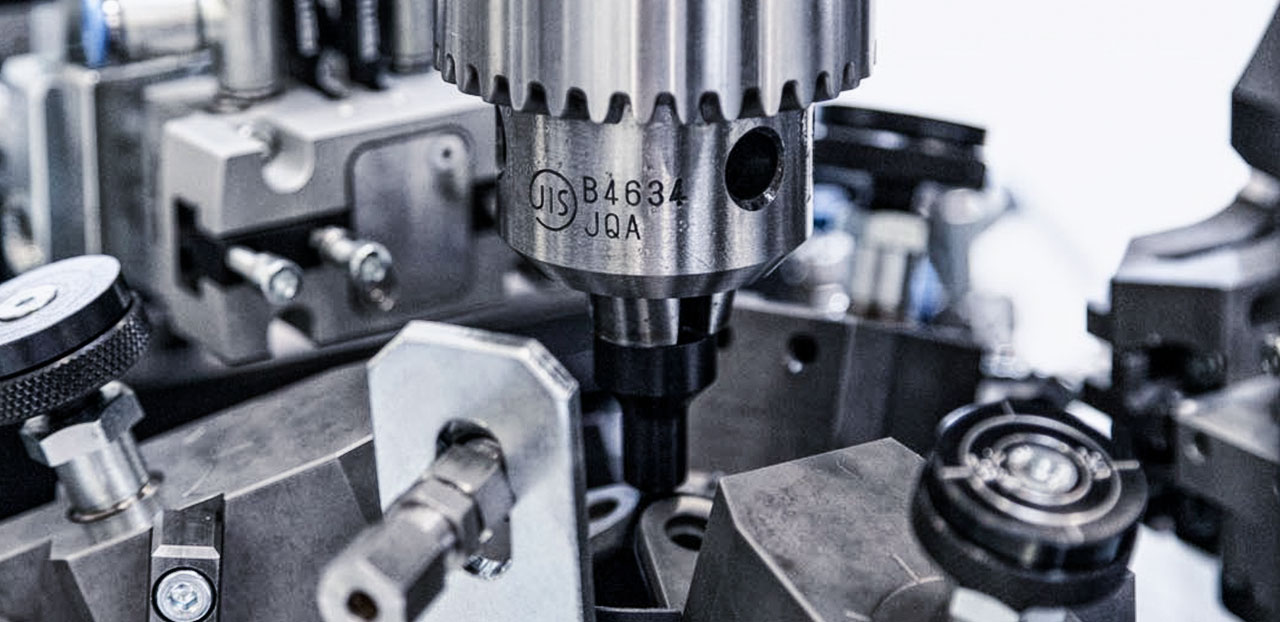

Hydraulic cylinders

Our product assortment includes uniquely designed and DIN/ISO compliant cylinders necessary for various industrial applications. Based on the experiences obtained in the last more than two decades we designed a basic cylinder that is characterised by long life-span and environment friendly technology. The seal-systems applied are able to ensure protection against leakage therefore the environmental pressure is low. The rest of the components – honed tube, hard chromium plated rod, piston and rod gaskets, fasteners, standard size OTC components – are the products of market leading manufacturers. Prior to delivery and assembly, cylinders are subjected to cyclic running and pressure tests on a final acceptance examination equipment designed and constructed by us. Our firm not only designs and manufactures unique or standard cylinders but also monitors their operation. In case of any eventual defect we make diagnosis and arrange for repair. Our service engineers use state-of-the-art technology for diagnosing and evaluating deficient cylinders.

Machine renovation

For us it is of outstanding importance that our partners’ production machines and machine lines could efficiently and continuously operate. Regular maintenance notwithstanding, certain renovations, modernising and efficiency improving reconstructions might become necessary. Based on preliminary status evaluation our engineers give professional advice, elaborate detailed quote regarding necessary modernisations, renovation. Our designing engineers elaborate redesign plans, and we procure or manufacture any replacing components. We undertake modernisation and successive automation of existing machines, machine lines, manufacturing lines as well as inserting new components into a manufacturing system. These possibilities extend the life span of the machines, increase their performance, however, if you need new machine turn to us and we will help.

UNIQUE MEASURING AND TESTING EQUIPMENTS

Unique test equipments, test terminals, test benches, measuring and checking machines can mainly be used in serial automobile manufacturing. By way of destructive or non-destructive procedures, our machines examine the mechanic and physical characteristics of components and subassembled units made of raw materials used in the course of manufacture. Conclusions deducted from data collected and values measured form ground for further developments and ensure the expected quality. Our equipments are PLC-controlled, can be controlled locally as well as remotely, in the course of planning and manufacturing we take the industry 4.0 actual requirements into consideration.

APPLIANCE MANUFACTURING

We design and manufacture – from specification up to commissioning – unique appliances for various special tasks. In addition to the accurate production process, high quality raw materials guarantee long life-span of our products and maximum satisfaction of our customers. The bulk of our appliances are used for clamping serially manufactured workpieces under processing but we manufacture appliances for measuring, assembly and appliances functioning in accordance with other special customer demands. For more information please contact our engineers.

DOWNLOAD

Jankovits Engineering: Image Catalogue

Our main machine types

- processing machines

- testmachines

- pressmachines

- machines for final inspection

- mounting equipments

- clamping and fixing technics

- development of components